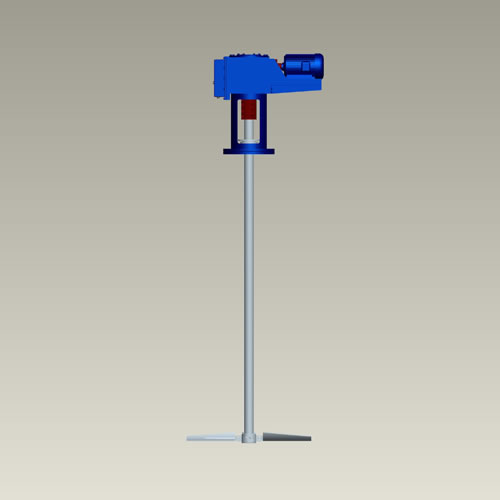

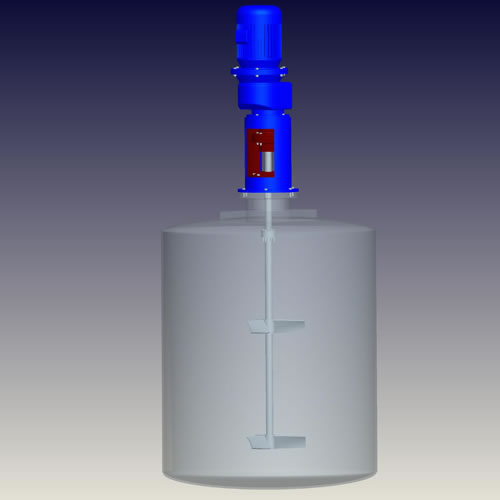

Gear Reducer Top Entry Mixer

Description

The series gear reduced top entering mixer is equipped with hard tooth surface cylindrical gear and circle-arc taper cone gear to decelerate the speed. The TFJ gear reducer top entry mixer adopts splash lubrication mode and special separation oil structure in order to prevent oil from leaking at any time. TFJ hard tooth surface cylindrical cone gear drive agitator employs square-box cordwood structure with multiple forms, which is convenient to assemble.

Remarks

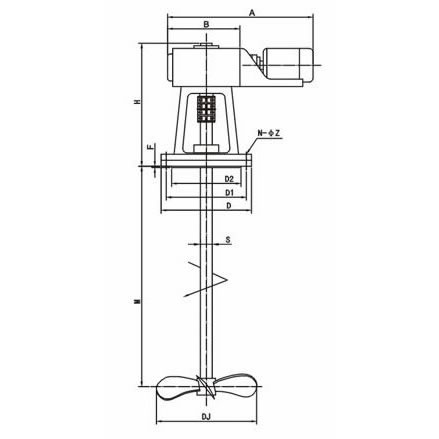

1. The weight of gear reduced top entering mixer in this form is the approximate weight, excluding the weight of mixing shaft and impeller inside the container.

2. The dimension M depends on the size of the user’s container.

3. The dimension D in the form is decided according to the mixing purpose of user, stirring volume and physical parameters, which should be subject to the real object.

4. Other rotary speed of this gear reduced top entering mixer may be customized by users.

Our mixer machine and mixing equipment mainly include agitator impeller, dispersator, portable agitator, magnetic stirrer, belt drive mixer, gear reduced top entering mixer, gear drive agitator, coaxial agitator, ribbon mixer, emulsion machine, pharmaceutical mixer, gold leaching equipment, wastewater treatment equipment and mixing support. We can make use of our technology resources to manufacture mixer machine like gear reduced top entering mixer and agitation equipment in accordance with the requirements of the users. We take responsibility for our gear drive agitators and commit to carry our one-year warranty.

Main Technical Standards of Gear Reducer Top Entry Mixer

| Series | Speed (rpm) | Power (KW) | S | D2 | D1 | D | N-ΦZ | F | B | A (max) | Weight (kg) |

| TFJ1 | 100(4P) | 0.55 | 30 | 245 | 295 | 340 | 8-Φ18 | 6 | 385 | 830 | 188 |

| 0.75 | |||||||||||

| 1.1 | |||||||||||

| 65(6P) | 0.55 | ||||||||||

| 0.75 | |||||||||||

| TFJ2 | 100(4P) | 1.5 | 40 | 290 | 350 | 395 | 12-Φ18 | 6 | 385 | 830 | 250 |

| 2.2 | |||||||||||

| 3 | |||||||||||

| 65(6P) | 1.5 | ||||||||||

| 2.2 | |||||||||||

| 3 | |||||||||||

| TFJ3 | 100(4P) | 4 | 50 | 320 | 400 | 445 | 12-Φ22 | 6 | 475 | 1033 | 350 |

| 5.5 | |||||||||||

| 65(6P) | 3 | ||||||||||

| 4 | |||||||||||

| TFJ4 | 100(4P) | 7.5 | 65 | 415 | 515 | 565 | 16-Φ22 | 8 | 555 | 1280 | 520 |

| 11 | |||||||||||

| 65(6P) | 5.5 | ||||||||||

| 7.5 | |||||||||||

| TFJ5 | 100(4P) | 15 | 80 | 520 | 620 | 670 | 16-Φ27 | 8 | 580 | 1382 | 750 |

| 18.5 | |||||||||||

| 65(6P) | 11 | ||||||||||

| TFJ6 | 100(4P) | 22 | 95 | 670 | 780 | 830 | 16-Φ30 | 8 | 650 | 1594 | 1000 |

| 30 | |||||||||||

| 65(6P) | 15 | ||||||||||

| 18.5 | |||||||||||

| TFJ7 | 100(4P) | 37 | 110 | 730 | 830 | 900 | 16-Φ30 | 12 | 970 | 2105 | 1400 |

| 45 | |||||||||||

| 65(6P) | 22 | ||||||||||

| 30 |

- In-Line Coaxial MixersIn-line mixers make it possible to pump, disperse, homogenize and emulsify materials with the same equipment. The inline mixers get rid of the randomness in the impeller mixing, thereby greatly reducing stirring time and enhancing product quality. In-line mixers are useful in chemical, food-processing, pharmaceutical and cosmetics production processes. In-line mixers can work...