DP Belt Drive Top Entry Mixers

Description

DP belt drive agitators adopt high strength belt transmission, which enables to change mechanical seal without removing the motor and emptying the materials in the tank. DP belt drive top entry mixer is widely used in power plant, desulphurization, methane fermentation, environmental protection, papermaking and petrochemical industries.

Features of DP Belt Drive Top Mounted Agitator

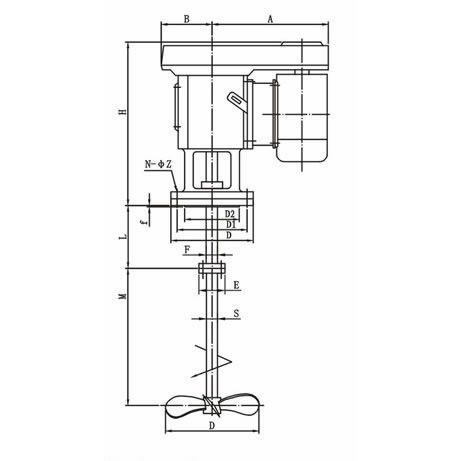

1. The belt drive top entry mixers consist of electrical motor, belt pulley, shaft, mechanical seal, leaking stop device and mixing impeller.

2. Characteristics of this DP belt drive agitator include high stirring effect, low power consumption as well as easy maintenance

3. This DP belt drive top entry mixer can adopt multiple sealing modes, such as the mechanical seal and packing seal.

4. With compact appearance, the belt drive agitator offers stable and reliable operation as well as long service life

Notice

When selecting our DP top mounted agitators, users need to point out using temperature and pressure, whether having the feature of solid particles and corrosive medium.

Main Technical Standards of Belt Drive Agitator

| Series | Speed (rpm) | Power (KW) | D | D1 | D2 | f | N-ΦZ | F | S | E | L | H | A | B | Weight |

| DP1 | 350(4P) | 0.75 | Φ315 | Φ285 | Φ240 | 3 | 8-Φ14 | 40 | 40 | 110 | 200 | 580 | 420 | 200 | 58 |

| 1.1 | 62 | ||||||||||||||

| 1.5 | 70 | ||||||||||||||

| 230(6P) | 0.55 | 64 | |||||||||||||

| 0.75 | 67 | ||||||||||||||

| 1.1 | 75 | ||||||||||||||

| DP2 | 350(4P) | 2.2 | Φ360 | Φ320 | Φ260 | 3 | 12-Φ18 | 50 | 50 | 130 | 200 | 600 | 450 | 220 | 94 |

| 3 | 98 | ||||||||||||||

| 4 | 105 | ||||||||||||||

| 230(6P) | 1.5 | 98 | |||||||||||||

| 2.2 | 110 | ||||||||||||||

| 3 | 125 | ||||||||||||||

| DP3 | 350(4P) | 5.5 | Φ400 | Φ355 | Φ295 | 3 | 12-Φ23 | 60 | 60 | 145 | 200 | 650 | 470 | 250 | 158 |

| 7.5 | 171 | ||||||||||||||

| 11 | 215 | ||||||||||||||

| 230(6P) | 4 | 170 | |||||||||||||

| 5.5 | 185 | ||||||||||||||

| 7.5 | 225 | ||||||||||||||

| DP4 | 350(4P) | 15 | Φ460 | Φ415 | Φ360 | 5 | 16-Φ23 | 75 | 75 | 185 | 200 | 880 | 650 | 350 | 264 |

| 18.5 | 300 | ||||||||||||||

| 22 | 340 | ||||||||||||||

| 230(6P) | 11 | 310 | |||||||||||||

| 15 | 360 | ||||||||||||||

| DP5 | 350(4P) | 30 | Φ460 | Φ510 | Φ450 | 5 | 16-Φ27 | 85 | 85 | 195 | 250 | 964 | 745 | 420 | 480 |

Remarks:

1. The weight of DP belt drive agitator in this form is the approximate weight, excluding the weight of mixing shaft and impeller inside the container.

2. The dimension M depends on the size of the user’s container

3. The dimension D in the form is decided according to the mixing purpose of user, stirring volume and physical parameters, which should be subject to the real object.

4. The weight of motor is the approximate weight of the general indoor motor, which may vary with the different manufacturers and types of motors.

5. Other rotary speed of top mounted agitator may be customized by users.

Top Mixer is equipped with various product portfolio of stirring devices. We can offer mixer machines like belt drive agitators which are more optimized and reliable as well as lower process maintenance and operation costs. We also provide mixing impeller, portable agitator, magnetic stirrer, DP belt drive top entry mixer, coaxial agitator, belt drive agitator, submersible mixer and mud scraper for customers to select. We adopt professional standard specifications and strict quality management system to ensure the mixing equipment as well as top mounted agitator meets the demands of customers.

- CR Gear Drive Side Entry AgitatorCR gear drive side entry agitator adopts the GLEASON gear to make transmission. This gear drive mixer is able to completely solve the leakage problem and ensure the working places safe and clean. There is no need to expel the materials when changing the mechanical seal, which just need to start the leaking stop device...