GXL Axial Flow Impeller

Description

GXL axial flow impeller is a composite construction impeller with high efficiency. As a corrosion-resistant impeller, this axial flow impeller uses a high grade vinyl ester resin system with strength and corrosion resistance being key features.

This axial flow impeller (corrosion-resistant impeller) is suitable for liquid mixing, dissolving, suspending, heat transfer, crystallization and reaction. The agitator impeller is designed to transfer the energy provided by the motor to the products in the most effective way and achieve the desired effect in the shortest time. This axial flow impeller is the best type for large-sized mixing tank.

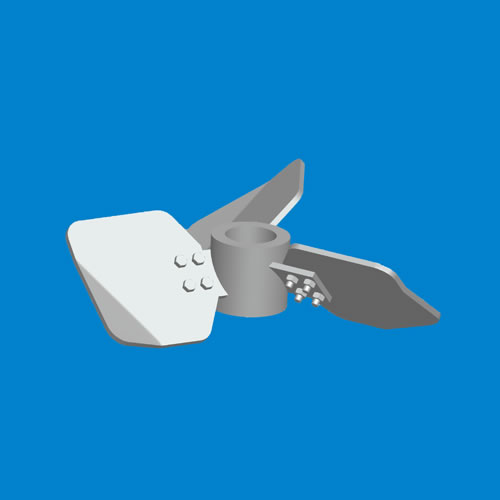

Features of Axial Flow Impeller

1. This corrosion-resistant impeller adopts composite structure and advanced vinyl plastics to manufacture, which can effectively prevent corrosion.

2. This axial flow impeller is suitable for low viscosity flow control applications in severe environment.

3. The corrosion-resistant impeller has high output flow rate and low shearing force.

4. With unique structure design, this agitator impeller offers more mixing efficiency than that of ZCX hydrofoil impeller.

TallKee Mixer Equipment is a professional corrosion-resistant impeller manufacturer and axial flow impeller supplier in China. With multiple experts, we are a national hi-tech enterprise specializing in the design, manufacture and research and development of agitator impeller (corrosion-resistant impeller). Our products mainly include axial flow impeller, agitator impeller, dispersator, portable mixer, magnetic agitator, belt drive mixer, scattering agitator, mixing agitator and mixing stands. We can offer axial flow impeller and mixer equipments which are more optimized and reliable as well as lower process maintenance and operation costs.

- ZYX Mixing ImpellerType ZYX mixing impeller (axial flow impeller) is the latest developed upwelling blade used in gas or liquid medium. The mixing purpose is to transmit the energy generated by the motor to the product in most efficient way in order to achieve the desired effect in a short time. The type, size and revolving speed of the mixing impeller...